A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Construction methods and materials may be chosen to suit the application, and will depend on the size of the vessel, the contents, working pressure, mass constraints, and the number of items required. Design involves parameters such as maximum safe operating pressure and temperature, safety factor, corrosion allowance and minimum design temperature (for brittle fracture). Construction is tested using nondestructive testing, such as ultrasonic testing, radiography, and pressure tests. Hydrostatic pressure tests usually use water, but pneumatic tests use air or another gas. Hydrostatic testing is preferred, because it is a safer method, as much less energy is released if a fracture occurs during the test (water does not greatly increase its volume when rapid depressurization occurs, unlike gases, which expand explosively). Mass or batch production products will often have a representative sample tested to destruction in controlled conditions for quality assurance. Pressure relief devices may be fitted if the overall safety of the system is sufficiently enhanced.

MOC : IS 2062 GR B

Size : 2400mmØ X 4200mm Height

MOC : IS 2062 GR B

Size : 2100mmØ X 3000mm Height

MOC : SA 240 GR 304

Size : 1500mmØ X 2680mm height

MOC : IS 2062 GR B

Size : 1800mmØ X 3720mm Height

MOC : SA 240 GR 316L

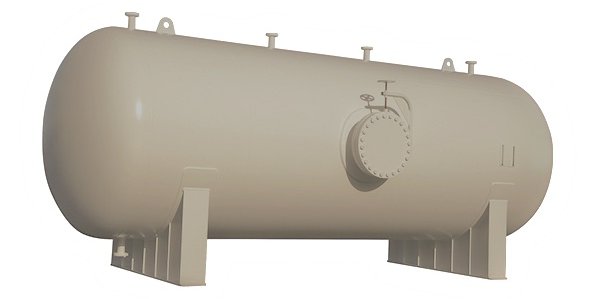

Size : 2850mm Ø x 7000mm Length